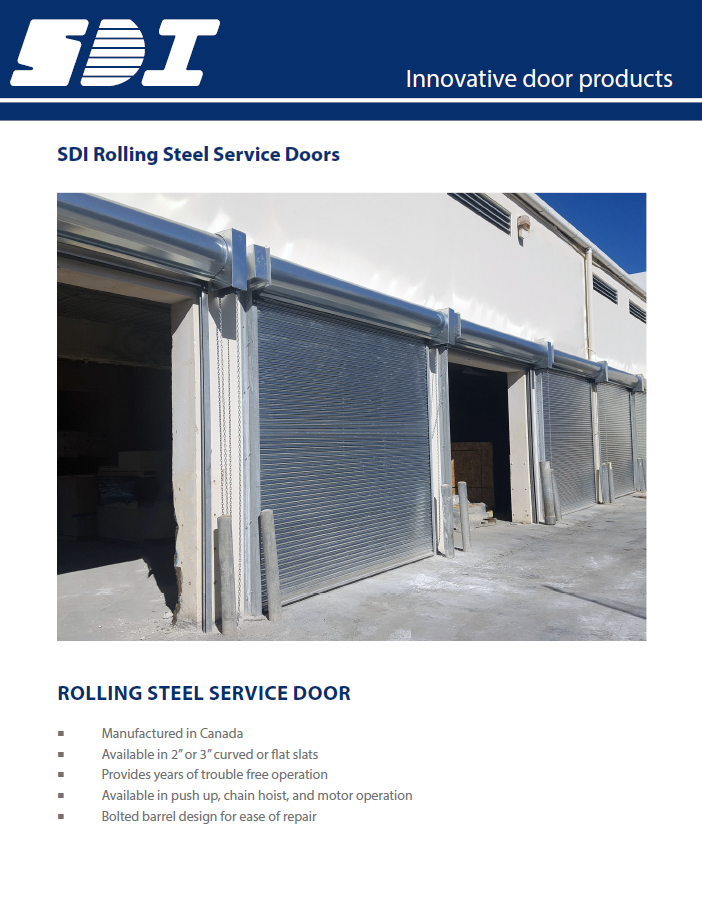

Rolling Steel Service Doors

SDI Rolling Steel Service Doors are manufactured in-house in Canada for industrial and commercial settings. Built to last, these doors provide years of trouble-free operation and easy repairs. With a variety of operations and mounting methods, these doors are a versatile and attractive choice for your space.

Door Features

- Rugged 2” flat slats or curved slats in 22 ga. steel

- Rugged 3” flat slats or curved slats in 22, 20, or 18 ga. steel

- G90 galvanized curtain and hood does not require further painting

- Structural angle guides and aluminum bottom bar are more durable and easier to repair than roll formed shapes

- Steel plate brackets are more durable than stamped steel bracket plates

- Heavy duty cast throats are more durable than stamped steel stops

| Bottom Bar | Extruded Aluminum |

| Bracket Plates | 1/4” thick steel in black finish |

| Barrel | Bolted design |

| Guides | Structural steel angle in black finish |

| Hoods | 24g steel - galvanized or grey finish |

| Windload | 20 PSF |

| Springs | Oil tempered torsion springs for 50,000 cycles |

| Maximum Size of Openings Tested | 2C & 2F : 14’-0” wide x 14’-0” high 3C & 3F: 20’-0” wide x 18’-0” high |

Specifications

Model

Operation

Finish

Mounting

Download

BP

Push Up

Galvanized

Between Jamb

BC

Chain Hoist

Galvanized

Between Jamb

BM

Motor (Gear Head)

Galvanized

Between Jamb

FP

Push Up

Galvanized

Face of wall

FC

Chain Hoist

Galvanized

Face of wall

FM

Motor (Gear Head)

Galvanized

Face of wall

FM

Motor (Gear Head)

Grey

Face of wall

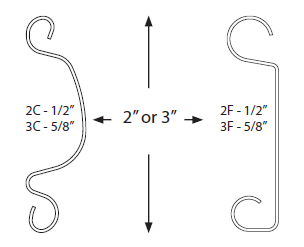

Slat Options

2" Flat and Curved slats available in 22 ga. steel

3" Flat and Curved slats available in 22, 20, 18ga. steel

Operation

- Push-up: BP, FP

- Chain Hoist: BC, FC, FC22

- Motor (Belt drive or Gear Head): BM, FM, FC22

Hardware Options

Slide Bolt Lock

Steel Double Angle Bottom Bar

Guide & Lintel

Guide windlocks for increased windload capability

Safety Options:

Featheredge/Bottom Sensing Edge (Wireless, coil cord)

Photoeyes (Reflective, Thru Beam)

Monitored Light curtain (36" or 72")

Motion Detectors

Traffic lights

Environmental Modifications:

Nema 7/9 Explosion Proof Motor

Nema 4 Water Proof Motor

Nema 4X Corrosion Proof Motor

Hot dip galvanizing for wet environments