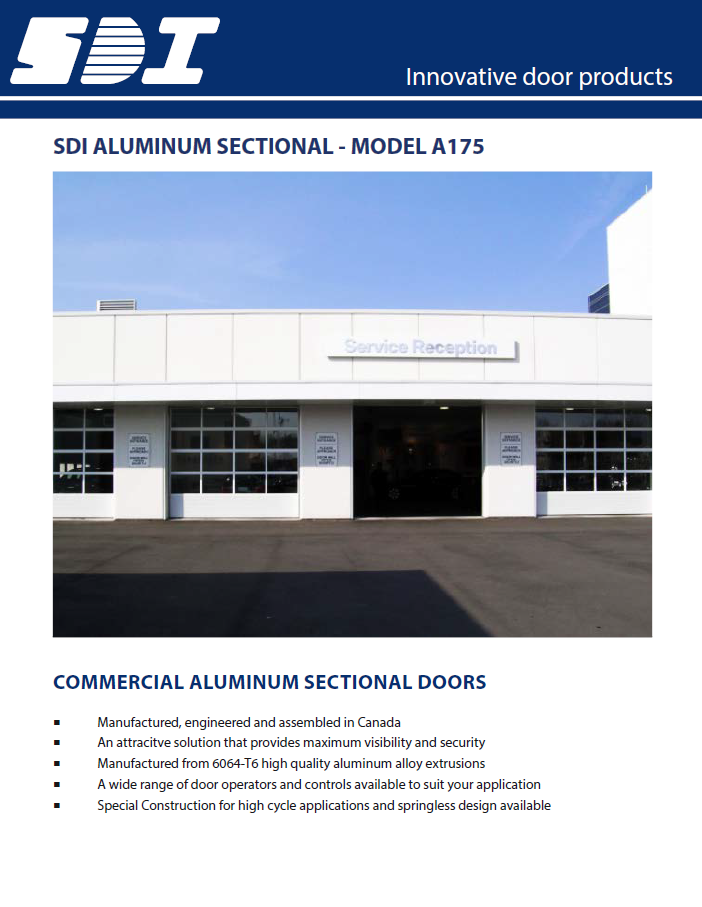

Aluminum Sectional Doors

Aluminum sectional doors from Service Door Industries are an attractive solution where unobstructed visibility is required. These doors are designed to withstand the rigours of busy service centres. The SDI reputation for quality sectional door products is clearly reflected in our aluminum products' distinctive appearance and performance.

Special construction for high cycle applications and springless design available

- SeeSpringless Sectional

Door Features

- Manufactured from 6064-T6 high quality aluminum alloy extrusions

- Special construction for high cycle and springless design available

- Designed to meet industry standard windload requirements

- Continuous internal reinforcement for hardware mounting

- Neoprene bulb weatherstrip with retainer. Two dual finned seals between sections

| A175 Sections | 1 3/4" thick |

| End Stiles | |

Single end roller brackets |

3 3/8" (86mm) wide aluminum |

Double end roller brackets |

6 3/8" (162mm) wide aluminum |

| Centre Stiles | 2" (51mm) wide aluminum |

| Pair of Meeting railes | 3 1/4" (86mm) high aluminum |

| Top and bottom rails | 3 3 /8" (86mm) high aluminum |

| Maximum Opening Width | 24'2"(7366mm) |

| Maximum Opening Height | 22 (6705mm) |

Panels

Finishes

Paneled sections

Fabricated from 0.05" (1.29mm) thick stucco embossed aluminum sheet

Kickproof bottom panel available in insulated and non-insulated.

Glazing Sections

1/8” (3mm) or 1/4” (6mm) thick:clear acrylic, polycarbonate, plain or tempered glass

5/8" (16mm) polycarbonate - tinted options available

1/2” (13mm) thick sealed plain or tempered glass & Self-aligning glazing retainer

1/2" (3mm) Sealed Lexan with MR10 coating

Operation

- Push-up

- Chain Hoist

- Motor

Hardware Options

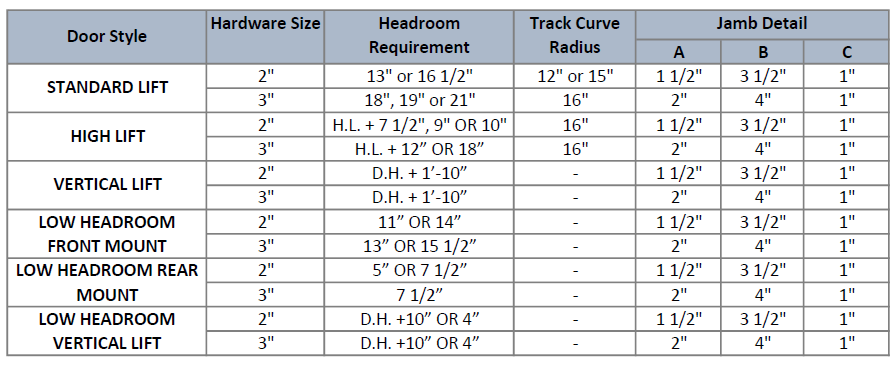

Download Clearance Diagrams

2" (50mm)

All door face hardware, tracks & mounting hardware and torsion assembly mounting brackets to have a zinc coating conforming to ASTM A653.

3" (75mm)

All door face hardware, tracks & mounting hardware and torsion assembly mounting brackets. Hot-dip galvanized with 380g./sq.m. (1.25 oz/sq.ft) -ASTM A525 - 9 lbs.

2" (50mm)

20mm (14ga) Commercial galvanized track, formed track 54mm (2 1/8”) overall outside dimension. Vertical tracks sloped for weather-tight closing; curves 305mm (12”) or 400mm (16”) radius, selection dependent on available headroom.

3" (75mm)

2.75mm (12ga) commercial galvanized track, formed track 80mm (3 1/8”) overall outside dimension. Vertical tracks sloped for weather-tight closing, 400mm (16”) radius.

2" (50mm)

2.0mm (14ga) thick commercially galvanized steel, rib enforced.

3" (75mm)

3.1mm (11ga) thick commercially galvanized steel, rib reinforced.

2" (50mm)

Optional at additional cost. Continuous track angle bolted adjustable type, fabricated from 2.0mm (14ga) commercially galvanized steel for full height of opening, fully adjustable to ensure weather-tight seal. Continuous angle to provide continuous track support for full opening height (combination angle and clip mounting not acceptable).

3" (75mm)

Optional at additional cost. Continuous track angle bolted adjustable type, fabricated from 2.4mm (13ga) commercially galvanized steel for full height of opening, fully adjustable to ensure weather-tight seal. Continuous angle to provide continuous track support for full opening height (combination angle and clip mounting not acceptable).

2" (50mm) & 3" (75mm_

Minimum 32mm x 32mm (1 1/4” x 1 1/4”) x 2.0mm (14ga) thick commercially galvanized perforated steel angles.

2" (50mm)

Steel rollers 48mm (1 7/8”) diameter with ten 6mm (1/4”) diameter ball bearings, 11mm (7/16”) diameter roller axles and inner and outer

ball races for hardened steel.

3" (75mm)

Steel rollers 73mm (2 7/8”) diameter with ten 8mm (5/16”) diameter ball bearings, 11mm (7/16”) diameter roller axles and inner and outer

ball races for hardened steel.

2" (50mm)

Fabricated from 2.4mm (13ga) thick commercially galvanized steel.

3" (75mm)

Fabricated from 3.1mm (11ga) thick commercially galvanized steel.

2" (50mm)

Helically wound torsion springs, manufactured from oil tempered spring wire, stress relieved, minimum 10,000 cycles. Aluminum diecast grooved drums and flexible galvanized aircraft cables, 7 x 19 construction, mounted on 25mm (1”) tubular steel OR 25mm (1”) CRS solid shaft keyed full length and mounted on ball bearings.

3" (75mm)

Helically wound torsion springs, manufactured from oil tempered spring wire, stress relieved, minimum 10,000 cycles. Aluminum diecast grooved drums and flexible galvanized aircraft cables, 7 x19 construction, mounted on 25mm (1") tubular steel OR 32mm (1 1/4") CRS solid shaft keyed full length and mounted on ball bearings.

2" (50mm) & 3" (75mm)

Interior Slide Bolt